The construction industry is in a constant state of evolution, always on the lookout for materials that offer superior qualities. One such groundbreaking advancement is the Thermo-Mechanically Treated (TMT) bar. Central to its exceptional properties is the process of heat treatment. In this article, we’ll delve into the profound impact of this process on the characteristics of TMT bars.

Understanding Heat Treatment

Heat treatment is a controlled process wherein metals are subjected to varying temperatures to alter their physical and mechanical properties. This process does not change the metal’s shape, but it significantly enhances its performance.

The Thermo-Mechanical Process Explained

The Thermo-Mechanical Treatment involves three crucial stages:

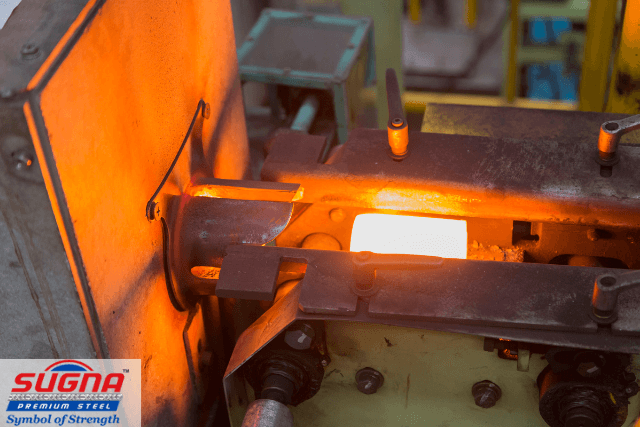

- Heating: The steel bars are heated to extremely high temperatures.

- Water Quenching: Rapid cooling is done by water jets, forming a hardened outer layer.

- Post-Quenching: The core remains hot, allowing it to temper and lending the bar its unique composite structure of a tough outer layer and a ductile core.

How Heat Treatment Enhances TMT Bar Properties?

Table: Benefits of Heat Treatment on TMT Bars

| Property | Impact of Heat Treatment |

|---|---|

| Strength | Increased yield strength, making them suitable for heavy-duty applications. |

| Flexibility & Ductility | Ensures bars can be bent or stretched without breaking. |

| Corrosion Resistance | The outer layer is less susceptible to environmental factors. |

| Weldability | Facilitates easier and stronger welding joints. |

| Thermal Stability | Improved resistance to high temperatures, reducing deformation risks. |

Heat treatment ensures that TMT bars achieve a fine balance between strength and flexibility, making them indispensable in modern construction.

The Superiority of Steel TMT Bars

Steel TMT Bars stand as a testament to the marvels of modern metallurgy. Their composite structure ensures they provide the best of both worlds – the strength to bear heavy loads and the flexibility to withstand natural forces like earthquakes. Their enhanced properties, thanks to heat treatment, make them a preferred choice over conventional steel bars.

The Expert Touch of SugnaTMT

In the world of construction, the quality of materials is paramount. SugnaTMT emerges as a beacon of excellence in this domain. Their Steel TMT Bars are a culmination of rigorous quality checks and the finest heat treatment processes. By entrusting experts like SugnaTMT, you ensure that every bar meets and exceeds industry standards.

Implications for Modern Infrastructure

The resilience and reliability of TMT bars play a significant role in modern infrastructure. Buildings, bridges, and dams constructed with these bars are not only safer but also have a longer lifespan. The heat-treated properties of TMT bars lead to structures that can weather both time and elements.

Conclusion

The transformative impact of heat treatment on TMT bars has revolutionized the construction domain. With an optimal blend of strength, flexibility, and durability, these bars are setting new benchmarks in infrastructure quality. As we embrace the future of construction, it’s evident that heat-treated Steel TMT Bars, especially those from industry leaders like SugnaTMT, will be foundational to tomorrow’s architectural wonders.