If you are into building construction or have been researching about it for your upcoming construction project, you must have realized that the steel used in construction comes in various qualities, grades, and forms.

Each type of steel has its own features and applications, the choice of the steel that you make goes a long way in determining the overall quality and durability of your construction.

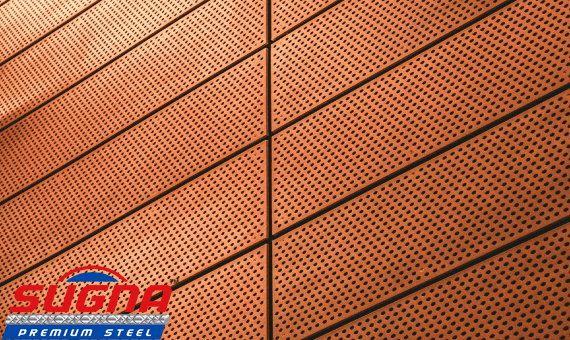

One of the most basic distinctions that have to be made at the starting level is between mild steel and high-strength steel. At Sugna TMT Bars, we offer all kinds of TMT steel to our clients. However, we also believe that it is important for the clients to be aware of the properties of each kind of steel and its uses so that they make the right choice.

So here, we talk at length about the differences between mild steel and high tensile strength steel. Let’s get started!

Mild Steel vs High Strength Steel

Mild steel and high-strength steel are both kinds of carbon steel. This means that both of them contain a portion of carbon. However, the difference comes in the amount o carbon present in each kind of steel, as well as the presence or absence of other metals. This leads to contrasting properties of both the steels, in terms of strength, ductility, durability, resistance properties, and more.

Differences between Mild and High Strength Steel

Composition

Both mild and high strength steels have a low carbon content of 0.6% to 0.8 %. However, high-strength steel also contains other alloy components such as Sulphur 0.05%, Manganese 0.60%, Silicon 0.20%, and Phosphorus 0.05%, which enhance and increase its tensile strength.

Strength

As the name itself suggests, mild steel is mild in nature, i.e. it has a lower tensile strength whereas high strength steel has a comparatively higher ranging tensile strength. However, it in no way means that mild steel is inappropriate for use in building construction, as we will see in the next few points.

In fact, mild steel has just the right amount of strength that is required for the construction of regular-use buildings.

Properties

Contrary to what you might believe, mild steel is not fragile in nature. It has an impressive quality and can’t be tempered easily. In addition, mild steel shows high malleability, making it ideal for use in structural construction. The only downside of mild steel is that it does not have great anti-corrosion properties due to the absence of alloys.

High strength steel, on the other hand, not only has higher tensile strength, but also great corrosion resistance due to the presence of alloys like manganese, silicon, and phosphorus.

Uses/Applications

Mild steel is appropriate for use in all kinds of structural construction, and is in fact, widely being used in the field. It is also used in reinforcing bars, roof covering, sheet piles, etc. High strength steel, on the other hand, is used in solid development constructions, and for industrial and commercial purposes like automobile manufacturing and weapon development.

Conclusion

Both mild steel and high-strength steel are good quality carbon steels, and you can choose the one which is most appropriate as per the requirements of your building construction.