TMT bars are thermo-mechanically treated bars made of steel. They have chemical components like sulfur, carbon, phosphorus, and scarce amounts of copper. The revival of the steel industry occurred around the year 1874. There had been the need for the invention of something ground-breaking when it comes to construction.

TMT bars provided that solution. Not only do they have an array of engineering and constructional benefits, but they are also decently priced. To know more in-depth about the features of TMT bars, keep reading.

1. Resistant from heat

Construction material needs to be heat-proof. In case of a fire, the basic structure of the building must hold up. TMT bars are not just used for building construction but also for making bridges, dams, flyovers, etc.

If these structures catch fire, TMT bars do not melt away easily. They help keep the cement together, at least till evacuation takes place. They can endure up to 600 degrees Celsius.

2. Flexible

TMT bars of superior quality and build can bend completely, that is, 360 degrees. Flexibility is essential in a TMT bar because it may have to absorb shocks from earthquakes or floods. There can also be a sudden change in the amount of load on the structure. For this reason, if the elongation capacity of the structure is bad, the building will crumble under pressure.

This flexibility comes from a particular style of milling which involves heating the steel to a very high temperature, rolling it to give the desired specifications, then cooling it down quickly and suddenly.

3. Relatively Inexpensive

The cost of TMT bars ranges from Rupees thirty-five thousand to forty thousand depending on their thickness and quality. That is not a very high price to pay, given that they last a lifetime. Once you use TMT bars to assemble your building, you cannot and will not require changing or replacing them. They can technically last more than a hundred years, which is an investment worth making. You can check the steel price in hyderabad.

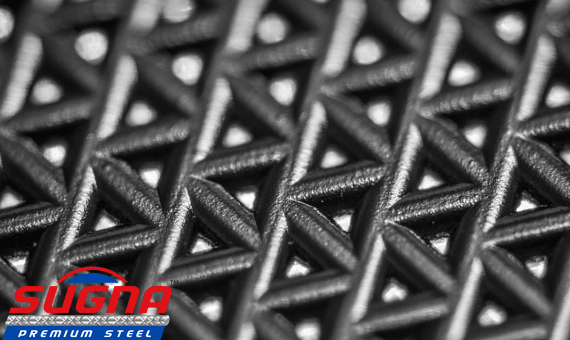

4. Bonds well with cement

The two things that help TMT bars bond so well with cement are adhesion and friction. When the cement shrinks, it binds itself tightly to the TMT bars. A particular water-cement ratio needs to be maintained for this bond to solidify and stay.

Adding substances like latex or methylcellulose also help in increasing the binding strength of the cement. The strength of the bond also depends on the amount of contact between the surface of the cement and the TMT bars.

5. Resistant to fatigue

Fatigue strength is the amount of cyclic stress that can be applied to a substance before it breaks down under pressure. It is the endurance limit of the steel, how much load the steel bars can handle.

The endurance limit of TMT bars depends on the type of the steel, the shape, and size of the steel, the process of its formation, etc. External factors like the loading cycle, corrosion, and welding process also make a difference. An increase in temperature reduces fatigue strength.

6. Corrosion-resistant

TMT bars are generally resistant to rust and corrosion. Steel tends to disintegrate in the presence of chloride ions. However, since TMT bars are thermally and mechanically treated, they do not share this property with steel.

Due to this property, they are well-suited to be used in humid and coastal areas. For further safety, some ways to prevent TMT bars from corroding are: storing them in a dry environment, avoiding putting too many bars too close to each other, and keeping them away from other construction material.

7. Saves a good amount of steel

TMT bars have high weldability, which ensures that less amount of steel is required to make the bars. Generally, the process of formation of TMT bars saves twenty percent more steel than other steel constructs.

Moreover, since they have low corrosion rates and high lifetime, the need to replace or change them is low. Ultimately, this saves steel for the long run and is also better for the environment. Products that are sustainable and environment-friendly are better investments from a financial standpoint too.

8. Easy to work with

TMT bars can be of nine different types. The three most commonly used types are Fe 415, Fe 500, and Fe 550. Fe 500 is generally considered by engineers to be the best as it has the perfect balance of strength and flexibility. Fe 415 is low on strength, while Fe 550 is low on flexibility.

Also, due to their thin rod-like shape and manageable size, it is easy to move them around. The construction workers do not get injured or harmed when they have to carry it around.

Takeaway:

All in all, if you want to get along with a construction or major renovation project, choosing TMT bars is a no-brainer. You not only get more durability but also the best bang for your invested bucks. You can connect with Sugna TMT which has the best steel plant in hyderabad.